Combustion of climate-damaging gases

– efficient, clean, safe.

Combustion of climate-damaging gases is efficient clean safe

C-deg offers itself as your reliable partner in this business!

Our over 25 years of professional experience, since 2008 as C-deg environmental engineering GmbH, enables us to successfully implement your task! We offer individual solutions in the form of flares and combustion chambers for the environmentally sound disposal of polluted gases – regardless of their origin, generation and calorific value.Innovative. Skilled. Reliable.

Our systems meet the requirements of the TA Luft. Air-polluting or even climate-damaging components can be converted into the less environmentally harmful carbon dioxide by combustion. Fixed flares are recommended above all when production processes are expected to release large quantities of polluted gas at irregular intervals. The areas of use for gas flares are manifold. C-deg supplies gas flares and combustion chambers of various constructions for a wide range of applications. From bio-gas and sewage gas flares to wood gas flares and systems for the combustion of exhaust air and non-combustible gases. Basic, open-burning or low-emission, low-temperature or high-temperature versions. Furthermore, we enable the recovery of the released energy for reuse.What sets us apart

Experience

Know-how

Quality

Service

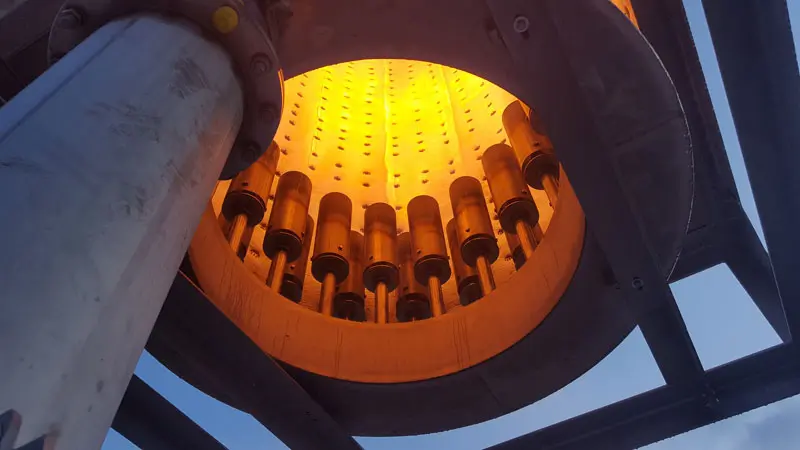

Our products

During the extraction of crude oil and natural gas, accompanying gases are produced which, due to their quantities, composition and chemical properties, cannot always be used for energy purposes. These gases are completely combusted in our (home-made) combustion chambers under high-temperature conditions up to 1200°C, which reduces their environmental impact to a minimum and at the same time complies with or significantly undercuts the requirements of the TA-Luft. Because this type of combustion does not produce any visible flames and only a hot transparent waste gas plume leaves the combustion chamber outlet, this type of system is generally not perceived as a classic gas flare and thus does not come under criticism from residents and environmentalists. The size of these combustion chamber flares depends on the firing capacity of the gases to be burnt. The power spectrum ranges from 100 KW to 40,000 KW. Even larger combustion chamber flares are possible in general, but their size is limited by their transportability. Another important characteristic of this type of plant is its turndown ratio. Here, the intensity of the minimum firing rate of a combustion chamber flare is considered in relation to its maximum firing rate. It is often necessary in terms of process technology for the flare to be able to process minimum gas quantities in addition to maximum gas quantities. There are various solutions for achieving a high turndown ratio, which we can discuss with you in advance in order to provide you with an optimal solution that both meets the process engineering requirements and is cost-effective at the same time.

The spectrum of industrial waste gases ranges from low-calorific weak gases to high-calorific fuel gases which, depending on their oxygen content, can have a considerable explosion potential. Therefore, there are no out-of-the-box solutions for this area, but always a solution adapted to the operational conditions. The handling of this type class of gases must always take place on the basis of an extremely carefully elaborated safety concept. In accordance with the ATEX directives and the emission requirements of the new TA-Luft, C-deg supplies state-of-the-art combustion technology, manufactured in Germany. In a C-deg combustion chamber, all polluted gases are burnt at over 1,000°C, practically free of pollutants. Allow the C-deg team to advise you.

Biogases and landfill gases are produced during the bacterial decomposition of organic substances, which produces methane as an oxidisable component. The gases therefore react similarly during combustion. ypically, biogas has a higher methane content, but the remaining component is almost exclusively the quenching gas carbon dioxide, which influences the ignition properties and flame stability in particular. Biogas flares from C-deg, like all our other flares and combustion chambers, are safety-engineered in accordance with the relevant guidelines for gas-engineered systems. The start and flame control of the flare are monitored by an automatic gas firing system that is fault-free according to EN-298. Depending on the gas conditions and customer requirements, the flares can be equipped with an integrated ATEX gas blower that sucks in and compresses the desired amount of gas. This way, the plant operator responsible for safety knows that he is operating a product that can withstand any safety-related test. For biogas plants that further process the biogas into biomethane by means of a treatment process, C-deg supplies combi flares whose burner circuits can burn both types of gas. C-deg offers flare systems from 20 KW to 40 MW. Depending on the requirements, the system can be designed as a cost-effective low-temperature flare or as a combustion chamber flare with high-temperature combustion > >1,000°C in accordance with TA-Luft. We offer larger plants on request. Each flare is equipped with one or more burner circuits, depending on the desired quantity control range.

The thermal decomposition of organic substances under exclusion of air is the process-engineering alternative to the classic biogas plants in order to obtain an energetically usable gas from biomass. The resulting wood and pyrolysis gases have a significantly different composition than biogas. In particular, the high hydrogen content and the equally high gas temperature must be taken into account here. Consequently, the flare and especially the burner for wood gas combustion must be adapted to these special requirements. C-deg also offers turnkey solutions for these cases. Please contact us specifically about our wood gas flares.

Genuinely lean gases are gas compositions consisting mainly of the non-combustible gas components nitrogen and carbon dioxide and having only a relatively small proportion of oxidisable components, so that such gases cannot be used for operation in conventional firing systems. Exhaust gases are a special form of lean gas. Exhaust gases are air loaded with hydrocarbon compounds, whose concentration is below the ignition limit and which therefore cannot be spontaneously combusted. However, due to the oxygen content, exhaust gases can quickly become explosive as the concentration of hydrocarbons increases and must therefore be considered separately from genuine lean gases in terms of safety. Regardless of their low energy concentration, both lean gases and exhaust gases are relevant to the climate and can be rendered harmless by thermal treatment. For the combustion of genuine lean gases, the innovative C-deg process for lean gas combustion is available, in which autothermal operation - i.e. without the firing of supporting gas - for lean gases with a methane content of up to 3% by volume is possible through the regenerative use of the energy on the exhaust gas side. In the combustion of exhaust gas, the strength of the hydrocarbon load is decisive for the type of treatment. If the load is far below the lower explosion limit, the exhaust gas can be fed to a back-up firing system as combustion air, whereby the exhaust gas is oxidised. If the load is more in the range of the lower explosion limit and above, the exhaust gas must be fed via a separate burner circuit, which may also be supported by a back-up firing system. C-deg flares offer controls that minimise the use of back-up firing.

The task of flares is to burn excess gases in an environmentally friendly manner. There are often tight limits to the use of this released energy due to the operational framework conditions. Nevertheless, it is desirable to use this surplus energy in order to avoid the negative image of energy destruction. C-deg offers two alternatives for high temperature flares: Alternative 1: Extracting a partial flue gas flow from the combustion chamber and supplying it to a flue gas/water heat exchanger. Advantage:The operation of the flare is not tied to the heat extraction. The flare can continue to be operated even if the heat is not extracted. Alternative 2: Installation of a flue gas/water heat exchanger at the flue gas outlet of the combustion chamber to utilise the complete flue gas flow. Advantage: The complete utilisation of the flue gas energy allows a considerably higher heat extraction. This makes the energy utilisation of the exhaust gas more efficient. However, there are also variants that can integrate the advantages of both alternatives. The exact possibilities of heat extraction must be examined for the individual application. In particular, the actual heat demand and the acceptance of the heat play a decisive role here. Our experts will be happy to discuss the subject with you and give you comprehensive advice. Afterwards, they will provide you with an offer tailored to your needs free of charge.

The pumping of gas primarily requires a gas blower that must be adapted to the specific requirements. Typical parameters are:

- Gas volume flow

- Gas temperature

- Gas composition

- Suction pressure

- Operating pressure

- Pressure measurement

- Temperature measurement

- Volume flow measurement

- Speed control

- Gas analysis

For applications where a flare is only needed for a short period of time or where flaring is not required at different locations at the same time, C-deg offers various types of mobile flares - both low-temperature and high-temperature versions. Mobile high-temperature flares are used, for example, in the oil and gas industry for hydrogen applications and by tank cleaning companies. Mobile low-temperature flares are used, among other things, during the commissioning of biomethane injection plants and during construction work on natural gas pipelines and tanks as well as biogas plants. Mobile flares from C-deg for rent C-deg offers various mobile flares for rent. The units can be operated with or without compressor, an individual adaptation for the respective application is carried out by our specialists. Please contact the C-deg sales team for further information or a quotation.

For further information

+49 431 220 17-0

Would you like to benefit from our all-inclusive service package? Make an appointment for a consultation now!

Our contact persons are available from Monday to Friday from 08:00 to 16:00.

We look forward to seeing you!